SUMMARY

In window and door fabrication, window machine consumables are the essential parts and supplies—like cutting blades, router cutters, welding plates, pneumatic components, clamps, sensors, and lubricants—that keep machines running efficiently and precisely. Unlike permanent fixtures, these components wear out over time and require regular replacement to prevent downtime, protect equipment, and maintain product quality. Managing a reliable inventory of high-quality consumables, rather than cheaper low-grade alternatives, ensures smoother operations, reduced costs, and consistent results. At WMC, we help fabricators identify, stock, and manage the right consumables to keep production lines efficient, reliable, and ready for growth.

ARTICLE

In the world of window and door fabrication, many beginners ask the same question: what are window machine consumables, and why are they so important? Simply put, window machine consumables are the parts, materials, and supplies your machines use during daily operations. They aren’t permanent fixtures like the machine itself; instead, they’re components that wear down, require regular replacement, and play a crucial role in keeping your production lines efficient, safe, and precise.

Understanding Window Machine Consumables

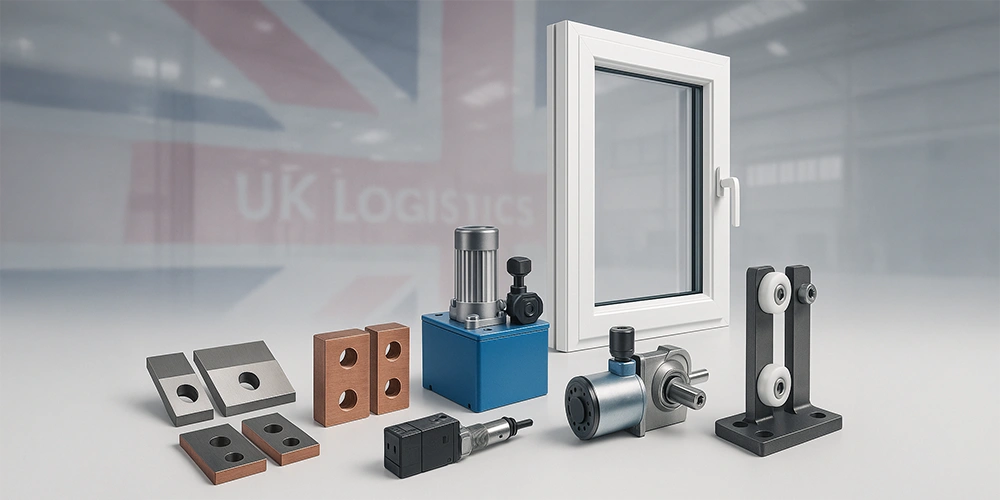

Consumables include a wide range of items, such as cutting blades, router cutters, welding plates, cleaning pads, clamps, pneumatic components, and electronic sensors. Each of these plays a specific role in the fabrication process. For example, sharp saw blades and router cutters ensure clean, precise cuts that minimize waste and rework, while clamps and pads keep materials steady for perfect joins and assemblies. Pneumatic parts keep automation running smoothly, and sensors make sure your machines perform at consistent levels of accuracy and safety.

Why Consumables Matter

Neglecting your consumables can lead to a host of problems: production slowdowns, poor product quality, increased wear on machinery, and even costly downtime. Stocking high-quality consumables is an investment in your efficiency and your reputation. For instance, a dull blade can not only compromise the finish of your frames but also strain your motors, shortening the life of your equipment.

Key Types of Window Machine Consumables

- Cutting Blades: Essential for uPVC and aluminium fabrication, ensuring clean, consistent cuts.

- Router Cutters: Ideal for detailed shaping and milling in uPVC profiles.

- Welding Plates: Provide strong, seamless joins that stand the test of time.

- Cleaning Pads and Abrasives: For finishing and polishing to achieve a professional look.

- Pneumatic Components: Valves, hoses, and cylinders that power automated functions.

- Clamps and Pads: Maintain precision by securing materials during fabrication.

- Electronic Sensors and Switches: Keep machines calibrated and running safely.

- Lubrication Systems and Fluids: Reduce friction and heat, protecting tools and extending their life.

- Protective Films and Covers: Safeguard products and machinery during use or transport.

- Small Hardware and Fasteners: Screws, bolts, and other essentials that keep everything together.

Managing Your Consumables Inventory

Effective inventory management is just as important as choosing the right consumables. Track usage rates, anticipate reorders, and schedule preventive maintenance to avoid surprises. Many fabricators adopt a predictive maintenance strategy—replacing consumables based on usage cycles instead of waiting for failures.

Choosing Quality Over Cost

It can be tempting to cut costs by opting for cheaper consumables, but low-quality parts often wear out faster or fail under heavy use. Investing in parts that meet or exceed OEM standards ensures better performance, less downtime, and longer machine life, ultimately saving money over time.

Partnering with Experts

At WMC, we’ve spent years helping workshops of all sizes manage their consumables more effectively. Whether you’re just starting out or running a high-volume production line, our team can help you identify the right consumables for your specific machines, train your staff on best practices, and plan a smart stocking strategy to keep your operation running smoothly.

Final Thoughts

Knowing what window machine consumables are, why they matter, and how to manage them is essential for any fabricator serious about efficiency and quality. By keeping your machines supplied with the right parts, you’ll minimize downtime, extend equipment lifespan, and consistently deliver high-quality windows and doors.

Ready to stock up or need guidance tailored to your production needs? Explore our full range of window machine consumables at wmconline.com or speak with one of our experts today. Let WMC be your trusted partner in keeping your production lines efficient, reliable, and future-ready.