SUMMARY

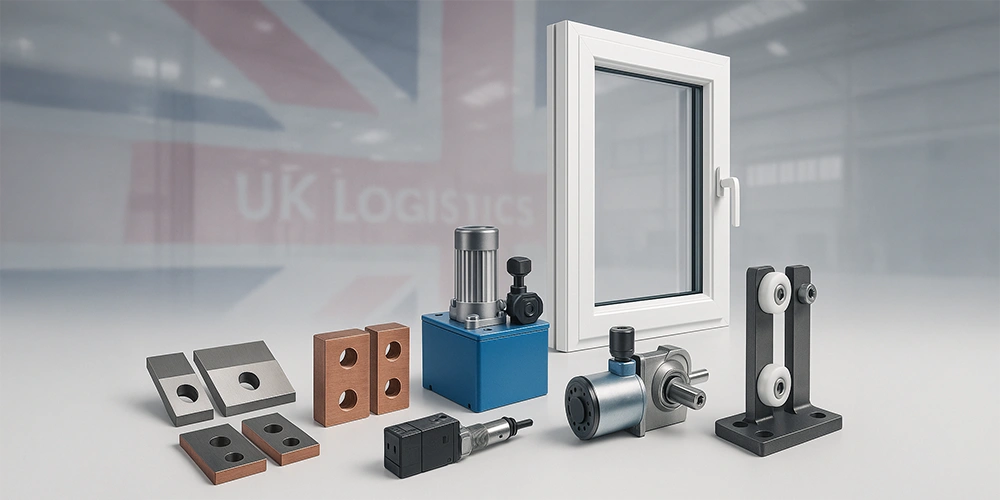

In the fast-paced world of window and door fabrication, efficiency and consistency hinge on having the right window manufacturing consumables on hand. From precision cutting blades, router cutters, and welding plates to pneumatic components, clamps, lubricants, sensors, and even small hardware, these essentials keep machines running smoothly and production lines free from costly downtime. Stocking high-quality consumables not only ensures clean, accurate, and safe operations but also extends the life of your equipment and maintains product quality. At WMC, we supply fabricators with premium consumables tailored to their unique needs, helping them stay ahead of production demands and deliver superior results every time.

ARTICLE

In the fast-paced world of window and door fabrication, efficiency, precision, and consistency are critical. Behind every seamless production line is a carefully selected inventory of window manufacturing consumables—the unsung heroes that keep your machines operating smoothly and your products meeting the highest quality standards. At WMC, we’ve been supplying the industry for years, and we know exactly which consumables every fabricator should have in stock to avoid delays, reduce downtime, and keep productivity at its peak.

This article takes a deep dive into the top 10 window manufacturing consumables that every workshop, large or small, should consider essential. Whether you’re producing uPVC windows, aluminium frames, or both, having these parts on hand can help you maintain operational efficiency and consistently deliver high-quality products.

High-Quality Cutting Blades

Cutting blades are at the core of any window production process. Precision saw blades, optimized for uPVC and aluminium, ensure clean, accurate cuts that reduce rework and material wastage. Over time, blades inevitably dull, which can lead to rough edges, inconsistent sizing, or even machine strain. Keeping a ready supply of sharp, high-quality blades ensures smooth production runs and helps extend the lifespan of your equipment.

Router Cutters

Router cutters are another must-have in the world of window manufacturing consumables. These tools are used for intricate shaping, milling, and finishing, particularly in uPVC fabrication. Dull or damaged cutters can compromise precision, so stocking durable, well-balanced replacements allows you to maintain consistent results without costly interruptions.

Welding Plates

For fabricators working with uPVC, welding plates are non-negotiable. They are critical for ensuring strong, seamless welds that stand the test of time. Over time, these plates degrade due to high heat and repeated use, which can compromise joint quality. Replacing them regularly with high-grade options keeps your finished products looking and performing their best.

Cleaning Pads and Abrasives

Cleanliness and finishing are key in window fabrication. Cleaning pads and abrasives are used for removing excess weld material and polishing frames to a professional finish. These consumables may seem minor, but they have a major impact on the overall quality of your products. Stocking a variety ensures you can achieve the perfect finish for every order.

Pneumatic Components

Modern fabrication lines rely heavily on pneumatics for automation, and components like valves, cylinders, and hoses are among the most critical window manufacturing consumables to have in stock. Even a minor failure can halt production, so having replacements ready minimizes downtime and keeps your production line running smoothly.

Clamps and Pads

These consumables play a key role in ensuring the stability and precision of your machinery. When clamps or pads wear out, you risk losing accuracy during cutting, welding, or assembly processes. Stocking quality replacements means you can maintain high levels of precision while also protecting your equipment from unnecessary wear and tear.

Lubrication Systems and Fluids

Or aluminium fabrication especially proper lubrication, is essential to reduce friction, prevent overheating, and extend the life of your cutting tools. High-quality lubricants and dispensing systems ensure smoother operations and help maintain the sharpness of blades and cutters, reducing both waste and downtime.

Electronic Sensors and Switches

With the increasing automation in the window manufacturing industry, electronic sensors and switches have become indispensable consumables. These parts help machines maintain calibration, detect errors, and ensure consistent performance. Keeping replacements in stock means you can resolve issues quickly, avoiding costly delays.

Fasteners and Small Hardware

From screws and bolts to specialised fittings, small hardware items are essential to daily operations. Running out of even the smallest components can slow or halt production, so maintaining a steady inventory helps you avoid unexpected interruptions and keeps projects on schedule.

Protective Consumables

Consumables like safety guards, covers, and protective films are often overlooked, but they play a big role in maintaining both product quality and workplace safety. Protective films, for example, keep frames clean and scratch-free during handling and transport, while machine guards protect operators and equipment from unnecessary damage.

Why Stocking the Right Consumables Matters

Every minute of downtime on your production line can translate to lost revenue, missed deadlines, and dissatisfied customers. By maintaining an inventory of the most essential window manufacturing consumables, fabricators can prevent avoidable delays, extend the life of their equipment, and consistently meet production goals.

Moreover, quality consumables directly impact the performance and lifespan of your machines. Inferior blades, cutters, or pneumatic parts may cost less upfront but often wear out faster or fail under pressure, leading to more frequent replacements and higher overall costs.

The WMC Difference

At WMC, we pride ourselves on supplying only the highest-quality window manufacturing consumables that meet or exceed OEM specifications. From precision-engineered cutting blades to durable pneumatic parts and everything in between, our range is designed to support the evolving needs of today’s fabricators.

We also understand that every workshop is unique, which is why we work closely with clients to recommend the right consumables for their specific machines and production requirements. Our team of experts can help you forecast your needs, plan your stock, and avoid the operational headaches that come with unexpected shortages.

Final Thoughts

Stocking the right window manufacturing consumables isn’t just about convenience—it’s about ensuring your workshop runs efficiently, your machines last longer, and your products consistently meet quality standards. By keeping these top 10 consumables in stock, you’ll be better prepared to handle the daily demands of fabrication while positioning your business for long-term success.

Ready to stock up on the essential consumables your workshop needs? Explore our full range of window manufacturing consumables at wmconline.com, or get in touch with our expert team for tailored advice. Let WMC be your trusted partner in keeping your production lines efficient, reliable, and ready for whatever comes next.