SUMMARY

Downtime in window fabrication can quickly eat into profits, and in today’s competitive market, even small delays can have a big impact. What many fabricators don’t realize is that the majority of stoppages can be prevented by focusing on one key area: the window machine components inside the equipment. High-quality parts such as blades, welding electrodes, hydraulic units, sensors, and profile handling systems play a much bigger role than most people think. They keep production running smoothly, reduce breakdowns, and extend the life of expensive machinery. By taking simple but proactive steps, like keeping critical spare parts for window machines in stock, sticking to a preventive maintenance schedule, working with trusted suppliers, and training staff to spot early warning signs, fabricators can significantly reduce disruption and consistently meet delivery deadlines. Ultimately, investing in the right window machinery parts doesn’t just keep machines turning; it protects production schedules, strengthens customer trust, and safeguards profitability.

ARTICLE

If you run a busy fabrication workshop, you’ll know firsthand how quickly machine downtime can snowball into a costly problem. It’s rarely just one isolated issue. A saw blade chips, a welding clamp wears out, or a sensor gives false readings, and suddenly the entire production line slows to a crawl—or stops altogether. When that happens, deadlines slip, labour costs rise, and the stress of missed targets begins to mount.

The truth is, most breakdowns don’t happen overnight. They often begin with something small, an overlooked component, a part that wasn’t replaced in time, or a shortcut taken with a lower-quality spare. Over time, those small details add up, and the result is lost hours and frustrated staff.

Downtime in window fabrication can:

- Delay customer orders and damage hard-earned relationships.

- Push up labour costs, as staff wait around or reschedule jobs.

- Trigger emergency repairs that cost far more than planned maintenance.

- Put extra strain on other machines, as workloads are shifted to compensate.

With production schedules tighter than ever, even a few hours of downtime can create a ripple effect that lasts for days—and in some cases, weeks.

Why Quality Window Machine Parts Make All the Difference

It’s easy to see why some fabricators are tempted by cheaper spare parts. On paper, they appear to save money. But in practice, generic or poor-quality replacement machine components are usually a false economy. They often wear out faster, don’t provide the precision modern fabrication requires, and in some cases can even damage the machine itself.

By contrast, using high-quality spare parts for window machines delivers benefits that show up daily in the workshop:

- Machines perform at their intended speed and precision.

- Breakdowns become less frequent, saving time and stress.

- Repairs are quicker and more straightforward when you can rely on well-made parts.

- Equipment lasts longer, protecting your initial investment.

It’s a simple but powerful equation: better components equal less downtime.

The Components You Can’t Afford to Neglect

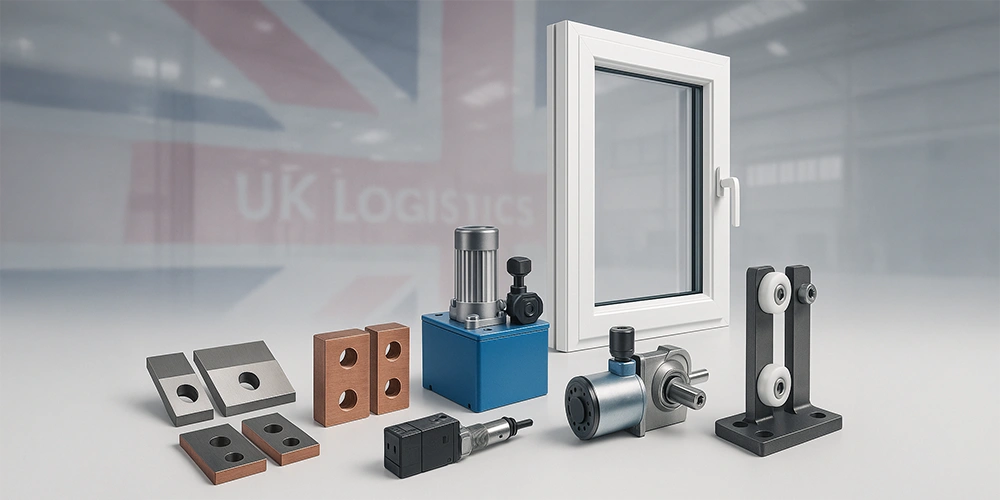

Not all parts are equal when it comes to keeping machines operational. Some window machine parts play such a vital role in day-to-day production that overlooking them can bring everything to a halt. A few of the most important include:

- Cutting blades and saw parts – Dull or chipped blades don’t just cut inaccurately; they also put extra strain on motors and bearings, leading to further issues.

- Welding electrodes and heating plates – If these are worn or damaged, welds become weak, uneven, or messy, often requiring rework that wastes valuable time.

- Hydraulic and pneumatic components – A small leak, damaged seal, or failing valve can instantly disable a machine, causing significant delays.

- Sensors and control systems – Modern fabrication relies heavily on electronic accuracy. Faulty sensors can stop production instantly or create hidden errors.

- Profile handling equipment – Rollers, clamps, and conveyors might seem secondary, but if they jam or fail, profiles stop moving and the whole line is disrupted.

Keeping these components in top condition can save not just hours, but sometimes days of lost production.

Practical steps to stay ahead of downtime

The good news is, reducing downtime doesn’t require complicated solutions, it’s about planning and consistency. Here are some proven strategies fabricators can adopt:

- Keep essential spares in stock – Don’t wait until a failure occurs to order replacements. Having key parts on hand means machines can be repaired quickly.

- Choose trusted suppliers – Building a relationship with a reliable provider of window machinery parts ensures you get consistent quality, fast deliveries, and expert advice when problems arise.

- Follow preventive maintenance schedules – Machines should be serviced regularly, with worn parts swapped out before they reach the point of failure.

- Upgrade when it makes sense – Sometimes frequent breakdowns are a sign the machine itself is outdated. Investing in newer window fabrication equipment can reduce downtime and lower overall costs.

- Train your team – Operators are your frontline defense. By teaching them to recognize early signs of wear, you can address problems before they cause serious disruption.

Downtime Prevention: A Competitive Advantage

Reducing downtime isn’t about luck—it’s about preparation, smart sourcing, and knowing which components matter most. When you consistently keep your production line moving, you gain a clear advantage: fewer delays, happier customers, and a stronger reputation for reliability.

At the end of the day, customers don’t care about the individual components inside your machines. What they care about is whether their windows are delivered on time and to the quality they expect. By investing in the right window machine components, you protect your output, your reputation, and your bottom line.

Why Choose WMC?

At WMC (wmconline.co.uk), we specialize in supplying high-quality window machine components to fabricators across the UK. We understand the pressures of running a busy workshop, which is why we stock everything from cutting blades and welding spares to hydraulic and pneumatic parts, all sourced for durability and precision.

Whether you’re looking to build a reliable stock of spare parts for window machines or need a fast replacement to get your production line back on track, we’re here to help. With WMC, you’ll have confidence that every part you order is fit for purpose and built to last.

Explore our full range of window machine components today and take the first step towards reducing downtime in your workshop.