In 2025, window manufacturers face new challenges, including stricter energy standards, rising demand for customisation, and increased automation. In this evolving landscape, replacement parts are more critical than ever to maintain uptime, ensure precision, and reduce waste.

We at WMC provide essential spare parts across all key production areas:

- Profile Processing: blades, cutters, welding plates, drill bits

- Glass Handling: washing brushes, sealant nozzles, vacuum pads

- Assembly: screwdriver bits, gasket tools, clamping pads

- Automation: sensors, PLC modules, pneumatic components

Our strengths include:

- UK-stocked parts for fast delivery

- Support for all major machine brands

- Help sourcing rare or discontinued parts

- Custom strategies for spare parts management

Proactive parts management reduces downtime, boosts quality, and extends machine life.

In the fast-paced world of window manufacturing, 2025 presents a new set of challenges and opportunities. With tighter energy standards, rising demand for custom frames, and the steady march toward automation, production lines are under more pressure than ever to perform flawlessly. Yet, one critical element that often goes unnoticed is also one of the most vital to long-term operational success: window machine replacement parts.

Modern window production relies on precision-engineered machinery, from cutting and welding to glazing and assembly. And every machine, no matter how advanced, will eventually require service and spare parts. In this article, we provide a practical, updated guide to essential replacement parts for today’s production lines, based on current trends, WMC’s experience in the industry, and what manufacturers should expect in 2025 and beyond.

Why Replacement Parts Matter More Than Ever in 2025

Window manufacturers are navigating a shifting landscape shaped by rising demand for energy-efficient windows, significant growth in PVC and aluminium frame production, increased automation and CNC integration, stricter lead time expectations from customers, and mounting pressure to reduce downtime and minimise material waste.

At the core of these pressures lies the performance and uptime of your machines. That’s where window machine replacement parts come in; not as a cost, but as an investment in consistency, quality, and operational resilience.

At WMC, we specialise in providing high-quality spare parts for window machinery, serving fabricators across the UK. Our customers count on us not just for parts, but for reliability, fast turnaround, and technical expertise.

Core Categories of Window Machine Replacement Parts

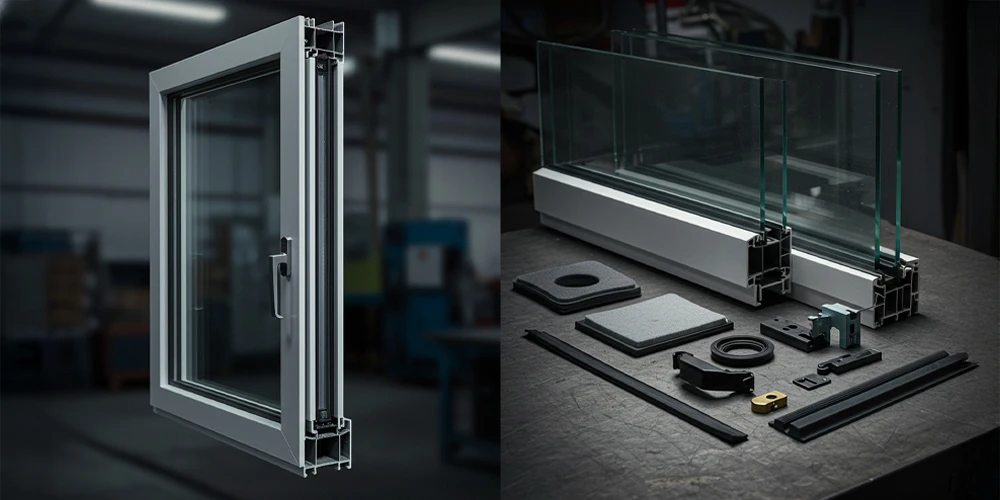

Whether you operate a compact fabrication unit or a large-scale automated facility, your production line typically involves three major processes: profile processing, glass handling, and assembly/glazing. Let’s explore the key parts within each stage.

- Profile Processing (Cutting, Milling, Welding)

This is where PVC or aluminium profiles are transformed into frame components. High stress and frequent use make the following parts essential to keep on hand:

Cutting Blades & Saw Discs

Used daily on mitre saws and double-head saws, these blades must stay razor-sharp to maintain cut accuracy. Dull blades result in material waste, inaccurate joints, and tool strain. In 2025, we’re seeing more manufacturers investing in carbide-tipped blades for durability.

Milling & End Milling Cutters

Used for creating drainage channels, handle cutouts, and locking system grooves. These tools need to be replaced regularly, especially when working with reinforced aluminium profiles. For extended life, opt for coated milling tools engineered for heat resistance.

Welding Plates & Electrodes

In PVC welding machines, electrodes and plates wear over time due to high heat and pressure cycles. Defective welds can lead to window failures down the line. Regular inspection and prompt replacement are crucial.

Drill Bits, Taps & Countersinks

Precision drilling is key for drainage and hardware holes. Using worn-out drill bits can crack profiles or misalign fastenings.

- Glass Handling & IGU Production

Insulating glass unit (IGU) fabrication requires a clean, controlled environment. Many components in this stage have shorter lifespans due to constant wear.

Washing Brushes & Rollers

Glass washers rely on high-quality brushes to remove dirt and residue before assembly. Over time, brushes lose stiffness or trap particles that can scratch glass.

Sealing System Nozzles & Pumps

Automated sealant application depends on consistent flow. Worn nozzles or clogged pumps result in uneven sealing, compromising thermal performance.

Desiccant Fillers & Valves

In double and triple glazing, desiccant is essential to moisture control. Faulty nozzles or damaged hoses can lead to IGU fogging, an expensive recall risk.

Vacuum Suction Pads

Glass handling robots and manual lifts use vacuum pads for transport. These pads need periodic replacement to prevent slippage or breakage.

- Glazing, Assembly & Hardware Installation

Final assembly is where frame components and IGUs are joined. These steps involve both manual and robotic operations.

Screwdriver Bits & Fastening Tools

Used for installing handles, hinges, and locks, these tools see high daily use. Stripped bits not only slow the process but can damage components.

Gasket Inserters

Specialised rollers and tools used to seat rubber seals around IGUs. If worn, they can cause improper gasket positioning, impacting the window’s air and water performance.

Clamping Jaws & Holding Pads

Hold the window in position during glazing or hardware fitting. Pads wear down with time and may lose grip or cause marks on profiles if not replaced.

Don’t Forget the Digital Side: Electronics & Automation in 2025

Many production lines are now semi- or fully automated, and digital spare parts are becoming just as important as mechanical ones.

Sensors & Limit Switches

Critical to machine safety and accuracy, these small parts often go unnoticed, until they fail. WMC recommends keeping spare sensors for key automation points.

Control Boards & PLC Modules

A faulty control board can shut down your entire line. We supply genuine OEM control units and provide sourcing help for legacy systems no longer in regular production.

Pneumatic Cylinders & Air Components

Many fabrication machines rely on pneumatic systems for movement. Over time, seals degrade, or valves wear out, keeping replacements in stock prevents downtime.

WMC’s 2025 Approach: Smarter Spare Parts Management

As a leading supplier of window machine replacement parts in the UK, WMC is committed to helping fabricators reduce machine downtime and keep production flowing. Here’s how we’re supporting the industry in 2025:

Stocking Essentials in the UK

We carry thousands of items in our UK warehouse, from standard blades and drills to niche OEM parts for older machines. Fast, tracked delivery across the UK ensures you’re never stuck waiting.

Support for All Major Brands

Whether you’re running machines from URBAN, Elumatec, Stürtz, Rotox, or others, we offer compatible parts, technical guidance, and ordering support.

Rapid Sourcing for Rare Components

Can’t find a specific part? Our team can source OEM and aftermarket alternatives, even discontinued or hard-to-find items, through our network.

Personalised Advice

Unsure which parts to stock for preventive maintenance? We’ll review your machine list and usage rates to help build a lean but effective spare parts strategy.

Proactive Maintenance = ROI

Stocking the right window machine replacement parts isn’t just a safety net, it’s a competitive edge. Here’s what you stand to gain:

- Reduced production downtime

- Improved machine lifespan

- Higher quality and fewer reworks

- Faster turnaround times

- Lower emergency repair costs

Manufacturers who view spare parts as an essential asset, rather than a backup plan. are better equipped to meet modern production demands.

Final Thoughts: Stay Ahead in 2025

The window industry won’t be slowing down any time soon. As automation increases and tolerances tighten, your equipment will need consistent care. A smart, forward-thinking approach to window machine replacement parts is a small change that can make a major difference.

At WMC, we’re proud to support fabricators across the UK with the tools, parts, and guidance they need to keep building. Explore our full range at www.wmconline.co.uk or reach out to discuss your parts needs, we’re always happy to help.

Contact our team at info@wmconline.co.uk or call us for expert advice.