SUMMARY

In window and door manufacturing, precision and efficiency depend heavily on the quality of consumables that keep machines running smoothly. Whether working with versatile uPVC or durable aluminium, the right components—such as blades, clamps, pads, valves, and sensors—ensure consistent quality, minimize downtime, and protect your bottom line. uPVC fabrication requires heat-sensitive, profile-friendly parts for clean welds and smooth finishes, while aluminium production demands robust, high-friction-resistant consumables for durability and precision. Using the right parts not only extends machine life but also boosts productivity and product quality. At WMC Online, we provide a full range of high-quality uPVC window machine parts and aluminium fabrication consumables, along with expert advice to help you choose the best solutions for your production line—keeping your operations efficient and your customers satisfied.

ARTICLE

In the world of window and door manufacturing, precision and efficiency are everything. Even the most advanced machinery is only as good as the consumables that keep it running. Whether you’re fabricating modern uPVC profiles or sleek aluminium frames, choosing the right consumables isn’t just about keeping your machines operational—it’s about delivering consistent quality, reducing downtime, and protecting your bottom line.

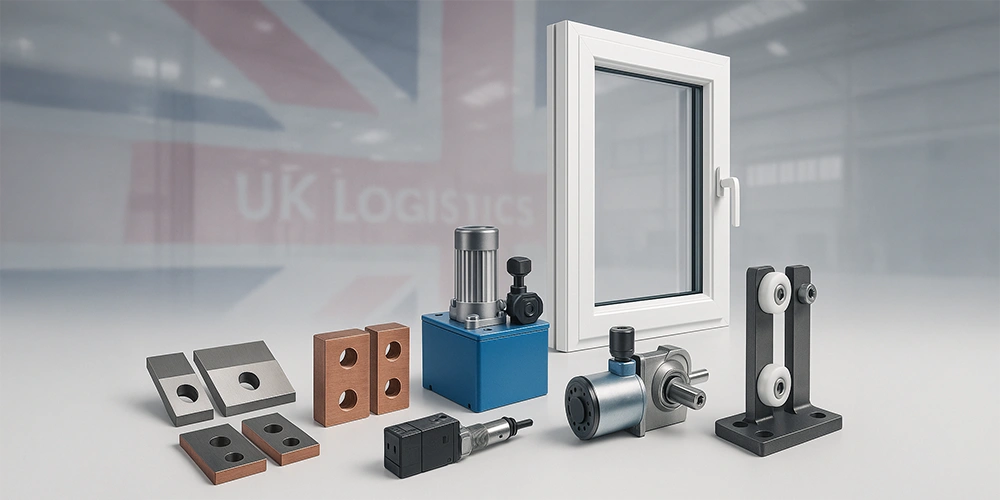

Consumables such as blades, clamps, pads, router cutters, and valves may seem like small components, but they play an outsized role in the performance of your production line. For manufacturers, investing in high-quality uPVC window machine parts or aluminium fabrication consumables can make the difference between smooth, efficient production and costly interruptions.

uPVC and aluminium each bring unique demands to the fabrication process. uPVC, a flexible thermoplastic, offers excellent insulation and versatility but requires softer handling to avoid surface damage or melting. Aluminium, on the other hand, is strong and rigid, demanding consumables capable of withstanding higher friction and stress. These differences mean that the consumables designed for one material rarely perform optimally with the other.

For uPVC fabrication, consumables need to be heat-sensitive and profile-friendly. Thermocouples, welding valves, and heat-proof cables are essential to ensure clean welds and seamless finishes. Router cutters and saw blades designed for softer materials help maintain precise edges without tearing or overheating. Clamps and pads must grip firmly while preventing pressure marks, which can compromise both appearance and structural integrity.

Aluminium fabrication

By contrast, calls for durability and precision above all else. Saw blades and router cutters need to be made from high-quality metals that can withstand repeated high-friction use without dulling too quickly. Stronger clamps and pads are required to hold rigid profiles securely, while extraction systems and hoses keep production areas clean by removing metal shavings efficiently. Here, durability isn’t a luxury—it’s a necessity for maintaining productivity and extending machine life.

No matter the material, certain categories of consumables are universally critical. Blades and saws ensure precise cuts; router cutters shape frames to exact specifications; clamps and pads secure profiles during processing; valves, sensors, and pneumatic components ensure smooth and safe machine operations; and thermocouples and regulators manage heat levels for accurate welding, particularly with uPVC. Bearings, brackets, and connectors quietly support the moving parts that keep production flowing smoothly.

Selecting the right consumables begins with understanding your machinery and your materials. A uPVC welder, for example, requires different parts than a milling station designed for aluminium. Using mismatched components not only accelerates wear and tear but can also compromise product quality or even damage expensive equipment. Trusted suppliers like WMC Online simplify this process by providing a wide range of uPVC window machine parts and aluminium fabrication consumables, along with expert advice to help you make the best choices for your production line.

Quality should always take precedence over cost-cutting when it comes to consumables. High-quality parts are more reliable, last longer, and ultimately save money by reducing the frequency of replacements and the risk of unexpected downtime. Preventive maintenance also plays a critical role. Keeping track of blade sharpness, clamp wear, and sensor performance allows you to replace parts before they fail, ensuring smoother, uninterrupted operations. Maintaining a buffer inventory of essential consumables—like pads, valves, and pneumatic cylinders—can also prevent production halts when parts need urgent replacement.

Aluminium and uPVC fabrication might share similar goals—producing accurate, high-quality frames—but their paths to achieving those results are very different. uPVC lines rely on heat-sensitive and precision-friendly consumables, while aluminium lines demand strength, durability, and robust extraction systems. Understanding these differences, and tailoring your consumable choices accordingly, is the foundation of a high-performing production setup.

At WMC Online, we understand that every second of uptime counts. That’s why we supply a full range of consumables—from blades and clamps to valves and sensors—sourced to meet the demands of modern fabrication lines. Whether you’re maintaining your uPVC window machine parts or upgrading your aluminium setup, having the right components on hand keeps your production line running efficiently and your customers satisfied.

Looking to upgrade your consumables or stock up on essentials?

Explore our full range of high-quality parts at wmconline.co.uk or get in touch with our expert team for tailored recommendations. With the right consumables, your production line can run smarter, longer, and with fewer interruptions—helping you deliver top-quality windows every time.