SUMMARY

In window and door manufacturing, having the right window machine parts at the right time is key to keeping production lines efficient and avoiding costly downtime. At WMC, we’ve learned which parts manufacturers rely on most—like precision blades, router cutters, clamps, pads, pneumatic components, and electronic sensors—because they keep machines accurate, consistent, and reliable. From uPVC consumables to specialized aluminium tooling, these parts ensure smooth fabrication and minimal interruptions, while proactive maintenance and high-quality components help extend equipment life, improve energy efficiency, and reduce waste. By investing in the right spares and expert support, manufacturers can keep their lines running, staff productive, and customers satisfied.

ARTICLE

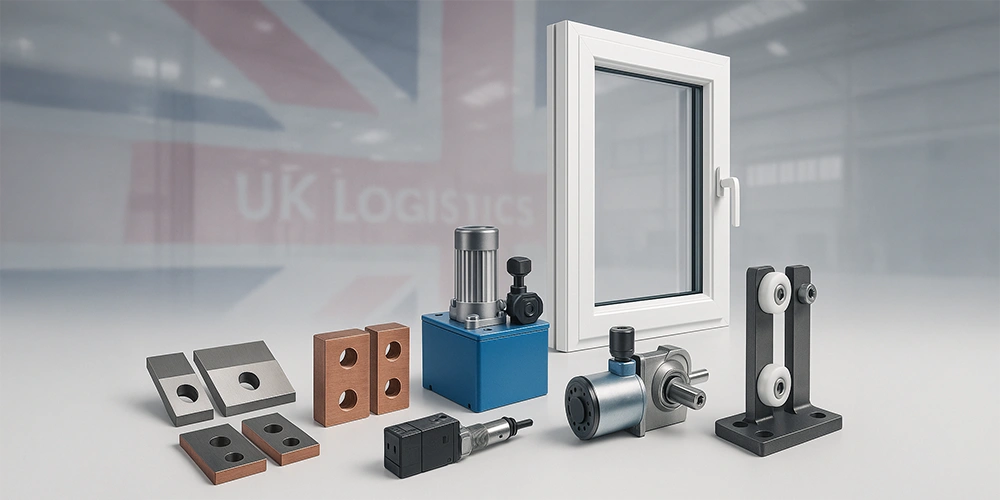

In the world of window and door manufacturing, having the right parts at the right time can make the difference between a smooth production run and costly downtime. At WMC, we’ve spent years supplying high-quality window machine parts to workshops across the UK and beyond, and we’ve seen clear patterns in the parts that manufacturers request most often. These aren’t just spare parts; they’re the lifeblood of a production line, keeping machines precise, efficient, and reliable.

This article takes you through our most requested window machine parts, why they’re so essential, and how investing in the right components can keep your operations running like clockwork. Whether you’re fabricating uPVC windows, aluminium frames, or a mix of both, these insights will help you make informed decisions about your consumables and spares.

cutting tools

One of the most frequently ordered categories we see is cutting tools, particularly precision saw blades and router cutters. The demands of modern window fabrication mean that clean, accurate cuts are a non-negotiable part of your process. Over time, even the highest-quality blades wear down, leading to rough edges, slower cutting speeds, or the need for additional finishing work. By keeping sharp, well-balanced blades on hand, manufacturers avoid unexpected stoppages and maintain the consistency their customers expect.

Another high-demand category is seals, clamps, and pads. These may seem like minor components, but they play a critical role in ensuring the stability and accuracy of your machines during operation. When these parts wear out, you risk losing precision in your cuts or welds, which can lead to wasted materials or quality issues that affect your bottom line. Replacing these parts proactively helps maintain the integrity of your production line and extends the life of your equipment.

pneumatic components

For many workshops, pneumatic components like valves and cylinders are also at the top of their spare parts list. These parts are the workhorses behind many automated processes, and even a small malfunction can bring production to a halt. Stocking up on quality pneumatic parts means you can address issues quickly without waiting for emergency shipments or paying premium costs for expedited delivery.

Electronics and sensors

Electronics and sensors are another area where we see consistent demand. As more window fabrication machines incorporate advanced automation, the need for reliable electronic parts has grown. Sensors, switches, and control units help keep your machines calibrated and safe, ensuring that every cut, weld, or drill is performed exactly as programmed. Faulty electronics can lead to production errors or even safety risks, making this a category where proactive maintenance really pays off.

uPVC and aluminium windows

For businesses producing both uPVC and aluminium windows, the needs can be even more varied. Aluminium fabrication often requires specialised tooling and handling parts due to the material’s different properties. We regularly supply custom router cutters, saw blades designed for non-ferrous metals, and lubrication systems to keep the process smooth and efficient. In contrast, uPVC production leans more on consumables like welding plates and cleaning pads to maintain the seamless finish that customers expect.

What ties all these high-demand parts together is the need for minimizing downtime. Every minute your line isn’t running is a minute of lost productivity—and potentially lost revenue. By understanding which window machine parts are most likely to wear out or need replacing, manufacturers can plan ahead, keeping spares in stock and scheduling maintenance during off-peak times to avoid interruptions.

At WMC, we also find that many customers appreciate the advice we provide on predictive maintenance. By tracking machine usage and understanding the typical lifespan of certain components, it’s possible to replace parts before they fail, rather than after. This approach not only keeps production lines moving but also protects more expensive components from damage caused by worn-out supporting parts.

sustainability

Another factor driving demand for certain parts is the increasing push toward energy efficiency and sustainability in manufacturing. Modern machines are being optimized for lower energy consumption and reduced waste, and the right parts play a role in achieving those goals. High-quality blades, for example, cut more cleanly and efficiently, reducing scrap and rework. Similarly, durable pneumatic components minimize air leaks that can waste energy and reduce performance.

Quality

Quality matters, too. One of the reasons customers keep coming back to WMC is our commitment to sourcing reliable, long-lasting parts. Cheaper alternatives may seem appealing in the short term, but they often wear out faster or fail under heavy use, creating more downtime and higher overall costs. By investing in parts that meet the original equipment specifications—or in many cases, exceed them—manufacturers safeguard both their machines and their reputation for quality.

Another trend we’re seeing in recent years is the increased need for customisation. With the rise of bespoke window designs and specialised profiles, many manufacturers require tailored parts to achieve the precision their projects demand. At WMC, we work closely with clients to source or produce components that fit their exact requirements, ensuring their production lines remain as versatile as their order books.

training and support

It’s also worth mentioning the importance of training and support when it comes to managing spare parts. The best equipment in the world won’t perform at its peak if operators don’t know how to maintain or replace parts correctly. We often advise clients on best practices for inspecting their machines, recognizing early signs of wear, and performing routine maintenance that extends the life of critical components.

In summary, the most requested window machine parts we supply—blades, clamps, pads, pneumatic components, electronic sensors, and custom tooling—are all critical to keeping production lines efficient and reliable. They might not always be the most glamorous parts of the process, but they’re the ones that keep everything running smoothly, day in and day out.

For manufacturers looking to stay competitive in 2025 and beyond, investing in quality spare parts and maintaining a proactive approach to machine maintenance is one of the smartest moves you can make. It keeps your lines running, your staff productive, and your customers satisfied.

If you’re ready to ensure your workshop is stocked with the right parts, explore our full range of window machine parts at wmconline.com. Or, if you’re not sure which parts are right for your specific machines, our expert team is just a call or email away. We’ll help you identify the components you need, plan for future maintenance, and keep your production line performing at its best. Let WMC be your trusted partner in precision, reliability, and performance.